Mold and tool manufacturing

Trouble-free production results in higher precision and a better surface finish

At Dohlen & Krott Werkzeugbau in Baesweiler, Germany, the focus is on highly complex, predominantly hardened injection molded parts. Although a full…

A unique combination of machining centers are convincing in terms of flexibility and precision

WESKO GmbH - A machine should be replaced due to its age and, in a further step, capacities increased with a larger machine. Also, the product range…

Supreme in precision and peripherals

Rauh + Kettner GmbH - Suitable tool changers, fixtures and improvised automation for milling were already available. But when the company Rauh +…

Parts production, general and micro mechanics

Highest precision in and for new dimensions

MIRAD Microwave AG in Wittenbach develops and manufactures assemblies for satellite communications. In connection with the development of a new…

In-house production made possible with flexible production islands

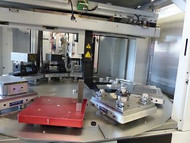

Swiss-Made: Manufacturing technology project of the future

Rychiger AG invested in the future of production technology with a self-sufficient…

Precision and dynamics lead to an efficient complete package

The OMB company in Flawil successfully covered the capacities of 2.5 machining centers with the first VERSA 825, installed in 2018. Over time, the…

Training

Into a successful future with modern equipment

Trainees expect a certain level of respect; you can't underestimate the demands that young people make. At least that's how Daniel Lohner, head of the…

TOP Machine Increases Motivation and Appreciation

BASF SE - Three years ago, Project 2020 was started, aiming at offering vocational training in accordance with the most advanced standards. For the…